Systems

We only apply the best products!

- Ardex

- Avista

- Bauer

- Dulux

- Epimax

- Flowcrete

- Fosroc

- Hychem

- Mapei

- Parchem

- Sika

- Tremco

- Ucrete

Polyurethane Cement

If your facility is subject to continuous or extreme thermal conditions, exposed to high levels of fats and oils or high levels of impact, then a polyurethane concrete system is a must. Industries that receive enormous benefit from polyurethane are, all food and beverage processing plants, chemical facilities, pharmaceutical producers, mining, cold/hot storage rooms.

Epoxy Flooring

Epoxy flooring refers to a very broad number of products, water based, high solids, self-levelling, trowelled mortar, decorative or vinyl flake, chemical and acid resistant and non-slip. There is an epoxy based product for most applications. Our expertise will ensure the best epoxy system is selected for your project.

Non-Slip Flooring

Poly-tech provides effective treatments for surfaces that become slippery when wet. Our anti-slip treatments are incorporated in a bespoke manner for your facility to ensure a code compliant finish is achieved to increase safety for employees, customers and the public.

Waterproofing Systems

An excellent waterproofing membrane system is essential to protect your infrastructure from water damage. As concrete behaves much like a sponge, soaking up water, it is imperative to have high quality concrete waterproofing to stop the ingress of water which creates cracking and far more severe problems.

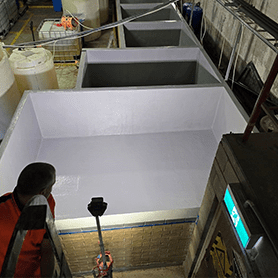

Acid & Chemical Resistant Coatings & Linings

Business process often requires the use of chemicals and acids to achieve delivery objectives. To provide long term protection to capital assets, acid and chemical resistant coatings should be at the forefront of business owners minds to maintain productivity and return on capital investment.

Concrete Repairs

Not only do we repair concrete in any condition e.g. Concrete cancer, cracks, major faults and fractures, we also smooth, prime and prepare the surface for protective concrete coatings to be applied. We can perform concrete repair or resurfacing on nearly any concrete surface. From floors, walls and columns to plinths, bunds and liners, the list is endless.

Electro Static Flooring

Anti -static flooring is designed to protect your work environment from the harmful risks of electrostatic charge commonly created by the friction of two materials. This application can be used across many business sectors such as military, electronic manufacturing and repair, chemical processing facilities, pharmaceutical and more.

Levelling and Screeding

We can provide a solution to your flat concrete floor that requires falls to drain with the use of high strength epoxy mortar, we can make water go where it needs to go. Self-levelling epoxies, polyurethanes and cementitious based products are suitable for repairing low points.

Epoxy Flake Flooring

Looking for something decorative yet durable and easy to clean?

We can enhance your ordinary concrete into something eye-catching and stylish. Flake floors are UV stable, waterproof, whilst being anti-microbial and resistant to chemicals. With a wide range of colours and non-slip textures to select from, Epoxy flake flooring is a cost effective and aesthetically pleasing solution.

Crack Repairs & Control Joints

The need for effective solutions for both crack repairs and control joints is paramount to the long term durability and stability of the concrete substrate. This is achieved through the cut jack trowel method, initially cut the perimeter of the desired location, jack hammering to remove degradation and debris and applying high strength epoxy mortar. Control joints are then diamond saw cut and filled with flexible mastic compound to prevent further cracking.

Fibreglass Systems & Repairs

Where protection against acids, including 98% Sulphuric is required, fibreglass linings are applied. Laminating a range of fibreglass cloths and fabrics using both vinylester and polyester resins provide incredible resistance and have proven to be a long-term solution time and time again.